Processing Corn Silage can be Advantageous for a Dairy Operation

A new corn silage called 'shredlage' is the buzz word in US dairying with nutritionists talking of higher feed intake and ease of digestibility and feed efficiency.Any dairy farmer wants to be more efficient, but not all are aware that corn silage processing can affect forage handling requirements and efficiency.

Phil Krueger, Mycogen Seeds dairy nutritionist and Dairy Herd Network says that, whether you process in the field or at the silo, the advantages include:

• Faster rate of silage fermentation

• More densely packed material in the silo

• Decreased dry-matter loss in silage storage

• Increased effectiveness of inoculants

Research at the U.S. Department of Agriculture’s Dairy Forage Research Center supports the idea that mechanical processing can improve feed efficiency and milk production in dairy cows, writes Mr Krueger.

However, the equipment is expensive and may not pay for itself in a smaller operation.

Larger farms are able to capitalize on new technology because of the volume they handle and size of their enterprise. Small operations need to look at custom operators for efficiency and to eliminate the high cost of purchasing large equipment.

University of Wisconsin researchers have studied the effects of corn processing and the chop length of corn silage, and the effects on intake, digestion and milk production for dairy cows. They found that processing corn silage will provide improved dry-matter intake, starch digestion and lactation performance.

Research results also showed less sorting and cob refusal in the feed bunk for total mixed rations containing processed corn silage.

In those studies, researchers found that the effect of the length of the particle size (a inch vs. ¾ inch) were minimal for animal performance in processed corn silage. However, a longer chop length did prevent the depression of fiber digestion that was observed at the shorter length while still achieving improved starch digestibility with processing, contributing to feed effciency.

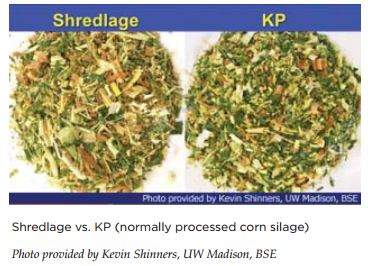

As a result, a new kind of corn silage, called shredlage, has entered the scene. While limited to last year’s data, Wisconsin researchers noted that for a one-shot trial, it looked pretty encouraging for milk production. The researchers also saw a trend for some higher intake with shredlage, and an increase in energy- and fat-corrected milk.

The technology, while it seems promising, probably is a few years away from being available to the average dairyman. The shredding processor unit is available only for Claas forage harvesters and comes with a price tag of approximately $29,200.

While the advantages of kernel processing are well-established, making shredlage is a technology that will require a few more research trials, a reduction in price and a few brave souls to try it on a field scale.

However, given that all the shredlage processors produced during its first commercial year was sold very quickly, the industry appears to be welcoming technologies allowing for increased effective fiber in corn silage while reducing the time and hassle of monitoring kernel damage of silage delivered to the storage structure.

So as you fine-tune your dairy operation to increase effciency and decide whether you are in the market for some new equipment to process your corn silage, be sure to consider the cost and benefits.

Six Silage Sampling Mistakes

Forage testing is critical to understanding the quality and nutrient content of your corn silage, but human error can infuence the accuracy of results. Avoid these common mistakes when collecting and sending corn silage samples for testing:

1. One-stop sampling – You must test a representative sample of the entire feeding surface of the pile, bunker or silo, not just one area. Collect multiple

subsamples from the silage surface and thoroughly

mix them. Then take a representative sample from the

mixed subsamples to submit to the lab. Or consider

submitting two or three representative samples from

the mixed subsamples and average the test results.

2. Hands down – If you collect handfuls of silage

with your palm down, kernels and other small

silage particles might fall out. Keep your palm up

and avoid shaking. Even better: Use a scoop or pail

to collect silage samples.

3. Garbage bagging – Save samples in zip-type plastic

bags, not garbage bags. Squeeze as much air from the

bag as possible before sealing. Some dairy producers

use a vacuum sealer made for sealing food to create

an air-tight package. Keep cool or freeze a fermented

sample prior to mailing to maintain its integrity in

transit.

4. Snail mail – A silage sample sent via the Postal

Service may degrade en route to the lab, especially

if mailed late in the week. Mail samples to arrive by

Friday. Overnight or second-day delivery is costly,

but when making a major forage change, ensuring

a timely report may be worth the added expense.

5. Mystery silage – Clearly identify your shipped

sample with your farm name, contact information

and sample identifcation. Be sure to specify the

analyses desired so the lab doesn’t need to contact

you with questions that could delay results.

6. Unsafe sampling – Safety is foremost when gathering corn silage samples. Never stand next to a silage face more than 10 feet high or get into a loader bucket.

Have the feeder mechanically remove silage and pull

it away from the face before attempting to gather samples.