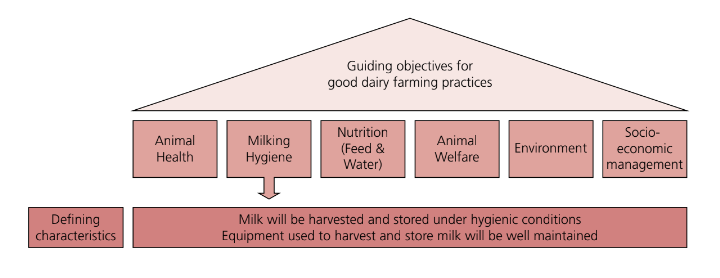

Guide to good dairy farming practice: Milking Hygiene

Best management practices for quality milkPart of Series:

< Previous Article in Series Next Article in Series >

This article is from the Guide to Good Dairy Farming Practices, originally written and published by the Food and Agriculture Organization of the United Nations (FAO) and the International Dairy Federation. The Guide has been written in a practical format for dairy farmers engaged in the production of milk from any dairy species. When adopted, it will support the production and marketing of safe, quality-assured milk and dairy products. Additional sections of the Guide will be published as an article series.

Milking is the defining activity of dairy farming. Consumers demand high standards of milk quality, so milking management aims to minimize microbial, chemical and physical contamination. Milking management covers all aspects of the process of obtaining milk from animals quickly an effectively, while assuring the health of the animals and the quality of the milk.

Consistency in the day-to-day implementation of milking procedures is an important part of good dairy farming practice for milking. This Fact Sheet describes practices that ensure milk is harvested and stored under hygienic conditions, and that the equipment used to harvest and store milk is well maintained. The suggested good dairy farming practices for milking hygiene are set out under the following headings:

• Ensure milking routines do not injure the animals or introduce contaminants into milk.

• Ensure milking is carried out under hygienic conditions.

• Ensure milk is handled properly after milking.

Ensure milking routines do not injure the animals or introduce

contaminants into milk

Identify individual animals that require special milking management

Individual animals should be easily identifiable by all people who come in contact with them. The system used should be permanent, allowing individual animals to be identified from birth to death. Additional temporary identification systems should be in place on farms to manage animals that require special handling at milking, such as treated or diseased animals, or animals producing milk that is not suitable for human consumption.

Ensure appropriate udder preparation for milking

Wash and dry dirty teats before milking. Only milk animals with clean, dry teats. Check the udder and teats for any abnormalities which may indicate clinical mastitis. The foremilk may be extracted and checked for abnormalities before each animal is milked. This may be a regulatory or contractual requirement for dairy animals in some countries.

Milk animals regularly using consistent milking techniques

Institute regular milking times and routines. Ensure good milking technique is consistently applied. Incorrect or variable milking techniques can result in a higher mastitis risk and injury to the animal. The correct technique for machine milking is to:

• prepare animals properly before milking;

• attach the cups to clean, dry teats;

• avoid unnecessary air ingress at cup attachment;

• avoid overmilking;

• remove cups gently; and

• when necessary, apply teat disinfectant to each teat after milking according to national recommendations and regulations.

The correct technique for hand-milking is to:

• restrain the animal to be milked using a method that does not cause pain or injury;

• ensure the milker’s hands are clean and dry;

• prepare the teats for milking, ensuring they are clean and dry;

• only use appropriate teat lubricants according to national recommendations and regulations;

• handle the teats gently, ideally using the ‘fist-grip’ method, avoiding any discomfort, pain or injury to the animal;

• use buckets that are non-corrosive, easy to clean and disinfect, and do not taint the milk;

• avoid contaminating the collected milk with foreign material such as dust, dirt, soil, urine, manure (faeces) and protect it from flies; and

• when necessary, apply teat disinfectant to each teat after milking according to national recommendations and regulations.

Segregate milk harvested from sick or treated animals for appropriate disposal

Animals whose milk is unfit for human consumption should be milked last or with a sepa- rate bucket or system. Store or discard abnormal milk in a manner appropriate to the risk posed to people, animals and the environment.

Ensure milking equipment is correctly installed and maintained

Manufacturers’ and local, regional or national recommendations should be followed for construction, installation, performance and maintenance of the equipment used for milking. Inspect and replace perishable components if evidence of wear is found. Materials used for milking equipment that come into contact with milk and with cleaning and disinfecting fluids should be made from adequately resistant materials and should not impart a taint to milk.

Follow the manufacturers’ instructions when using cleaning and disinfecting agents on milking equipment, including any requirements to rinse following application. Only use Fact sheets 19 cleaning and disinfecting agents approved for use by the relevant authority. These chemicals should be used in a way that ensures they do not have an adverse effect on the milk or milking equipment. Store all chemicals, other than those in routine use, in a lockable area away from the milk storage area.

Ensure a sufficient supply of clean water

A sufficient supply of clean water should be available for milking operations, for cleaning

the equipment that comes into contact with milk and for cleaning the milking area.

The quality of the water should be suitable for its intended use. Standards regarding the

quality of water used in milk production are mandated in many countries, including the use

of potable water in cleaning surfaces that come into contact with milk.

Ensure milking is carried out under hygienic conditions

Ensure housing environment is clean at all times

A high standard of cleanliness should be maintained at all times in housing areas to

decrease soiling of the udder and so protect udder health. The housing area should:

- be designed to provide good drainage and ventilation and to avoid animal injury

- be of suitable size and designed to cater for the size of the animal and the herd

- have adequate loose bedding which is maintained in a hygienic condition

All stalls and beds should be kept clean and dry (eg by replacing the bedding frequently). Regularly clean or scrape passageways to remove manure.

Ensure milking area is kept clean

The milking area should be designed to allow it to be kept clean and tidy. It should:

- be easy to clean

- have a clean water supply

- have waste handling facilities

- have sufficient temperature regulation, ventilation and light

Construct holding yards to enable a high standard of cleanliness to be maintained

Ensure the milkers follow basic hygiene rules

The milker should:

• wear suitable and clean working clothes;

• keep hands and arms clean especially when milking;

• cover cuts or wounds; and

• not have any infectious disease transmissible via milk.

Ensure milking equipment is cleaned and when necessary, disinfected after each milking

Establish a routine to ensure milking equipment is clean before each use. If mobile milking equipment is used, this may mean cleaning between each use. Use chemicals approved for the cleaning and/or disinfecting of milking equipment. Use water of suitable quality heated to the required temperature. Milk contact surfaces should be disinfected as required and in accordance with national recommendations and regulations.

Ensure milk is handled properly after milking

Ensure milk is cooled or delivered for processing within the specified time

Cool milk as soon as possible after milking to the required storage temperature and within the specified time. Cooling times and storage temperatures should conform to limits set by the relevant authority. Limits on the time taken between milking and delivery to the milk collection centre may exist in developing countries where the cooling or processing of milk is undertaken off the farm.

Ensure milk storage area is clean and tidy

Milk should be stored away from the milking area. The milk storage area should:

• be clean and clear of accumulated rubbish, any products or chemical substances not in constant use and any feedstuffs;

• have hand washing and drying facilities; and

• be easy to clean and have pest control practices in place.

Ensure milk storage equipment is adequate to hold milk at the specified temperature

The storage equipment should be capable of holding milk at the required temperature until collection, and be constructed of materials that do not taint the milk. Bulk tanks should be built to recognized standards and milk refrigeration systems should have a regular maintenance and service programme to prevent breakdowns. The bulk tank should be equipped with a thermometer to check the temperature of the milk and appropriate records kept of storage temperatures. Ensure that all of the equipment is working properly.

Ensure milk storage equipment is cleaned and when necessary, sanitised after each milk collection

To ensure milk storage equipment is clean before use, clean and, when necessary, sanitize it after each milk collection. Milk contact surfaces should be sanitised as required in accordance with national recommendations and regulations.

Ensure unobstructed access for bulk milk collection

Provide unobstructed access to the milk storage area to enable the safe collection of milk. Access to the milk collection areas should be free of animal pathways, mud and other potential contaminants.

Reference: FAO and IDF. 2011. Guide to good dairy farming practice. Animal Production and Health Guidelines. No. 8. Rome.