Q&A with Amlan’s President: How can dairy farmers mitigate the effects of mycotoxins?

Dr. Wade Robey speaks about the global mycotoxin challenge and how it’s impacting dairy producers’ bottom lineDr. Wade Robey, president of Amlan International, speaks with Global Ag Media’s Sarah Mikesell at the World Dairy Expo in Madison, Wisconsin about mycotoxins, their impact on the dairy herd, Amlan’s mycotoxin research and how a multi-step approach can keep mycotoxins from harming the herd.

How do mycotoxins impact the dairy herd?

Mycotoxins are impactful to dairy in several different ways, and the impact depends on which mycotoxin we're discussing and whether they're present in the ration alone or in combination with other toxins. Mycotoxins can have a direct impact on:

- rate of gain

- feed conversion

- reproductive fitness, including parturition and abortion rates

- milk production

- component yield of milk

Are all mycotoxins the same?

There are more than 400 known mycotoxins but just a handful that we monitor from an economic standpoint because they have the most significant impact on animals. Mycotoxins are definitely not the same in terms of their impact and levels of toxicity. Certain mycotoxins like aflatoxin are sensitive to the animal at rates in the parts per billion range, while other mycotoxins are sensitive at parts per million.

They are also more damaging if they're in combination. So certain mycotoxins can be present in a diet in multiple ways. Those then have an additive effect and impact the animal more significantly.

What does your mycotoxin research in dairy suggest?

In the young dairy animals, mycotoxins can impact growth, rates of feed conversion and efficiency of the diet. Mycotoxins in lactating cows can impact rates of milk production but also the component yield. All of these have direct economic impacts on the farmer and can reduce the profitability of the operation.

How does Calibrin®-Z improve animal and economic performance?

Calibrin-Z is one of Amlan's premium products that is broad spectrum in its efficacy in an animal ration. Calibrin-Z will bind both bacterial toxins that are present based on pathogenic bacteria being prevalent in the digestive tract and mycotoxins that are found in the feed coming from fungal origin when the crop was either in the field or during the ensiling process.

Calibrin-Z can improve the health and fitness of the animal while preventing the negative effects mycotoxins show in terms of direct damage to the animal's tissues, primarily in the liver, kidney and reproductive organs.

Thus, Calibrin-Z provides broad-spectrum protection, allowing the animal to be healthy and reach its optimum potential and yield the best rate of economic performance possible.

Producers know that feed is the #1 cost of production and makes up about 70% of their input cost. Any reduction in feed efficiency, conversion or nutrient utilization provided in the diet by nutritionists have a direct economic impact on their bottom line.

Certainly, mycotoxins impact milk production and maximizing milk production is critical to our dairy producers, and milk component yield is also important. So, those direct economic impacts play into the return on investment that a producer will see with Calibrin-Z.

Are mycotoxins a problem for producers around the world?

We see evidence of mycotoxin damage all around the world. Globally, we see well over $1 billion in negative economic impact from just aflatoxin each year in terms of reductions in animal performance and productivity. Again, the economic impact of mycotoxins is very significant.

Mycotoxins come from fungal growth in the food crop itself, so they can be present wherever grains or products that are used for forages are grown. Different mycotoxins can be more or less prevalent in each region during the year, depending upon the growing season and particular fungi that are present in those regions.

Typically, the most impactful are toxins like aflatoxin, zearalenone, T2 toxins, ochratoxin, and deoxynivalenol. These are all the key mycotoxins that we watch very closely.

If a dairy producer has a mycotoxin challenge on farm, what are the steps to manage it?

Step #1: We recommend that a producer and their consulting technical staff like their nutritionist and/or veterinarian monitor mycotoxins in their region on an annual basis. It’s important to pay attention to what's coming out of the local university offices, and often government agencies will share information on which mycotoxins are prevalent in a region. So, the first step is understanding what the toxin load is in a given year.

Step #2: The second step is developing a surveillance program on your farm, which includes doing analytical and diagnostic work to determine the presence of toxins with your local university extension office, contract labs or using on-farm ELISA kits.

Step #3: The final step is mitigation strategies. Using Amlan’s clay-based binders in animal feed will bind to the toxin, remove it from the digestive system and prevent its absorption and internal damage in the animal.

This multi-step approach can help solve the issue of mycotoxins rather than just react to them once an animal starts to have an issue.

Mycotoxins seem tricky – different mycotoxins seem to pop up year to year?

Yes, the fungal species themselves that are growing in the field, whether that's an aspergillus, fusarium, penicillium, these really are not harmful to the animal, it depends on whether the mycotoxin is produced. The mycotoxin is a toxin or a metabolite that is produced during the growth of the organism.

Once mycotoxin is present, though, it's not removable, so you can't remove the mycotoxin through an ensiling process or through the TMR preparation. You actually have to bind it once it's present. Again, the mycotoxin threat can differ year by year, region by region, in terms of which ones are most prevalent.

Some mycotoxins are more directly damaging to the animal, making them more concerning. For example, in dairy they can sometimes be found in the milk if the animal consumes high enough rates. This can be a pretty serious issue, but if you have the right surveillance and mitigation strategies, you can avoid this.

You could simply treat and mitigate, but that’s an expensive and risky approach. We recommend a combination of good herd management – good biosecurity, proper nutrition, surveillance, then mitigation when needed. This combination creates an efficient solution that lowers the cost of mitigating mycotoxins and offers the best results.

Clay-based binders are an important part of the strategy because toxins are typically going to be present. Since they're not visible, it's hard to know which ones you are dealing with, so you must stay on top of your surveillance. Having an ongoing mitigation strategy is the best way to deal with mycotoxins for the health of the animals and from an economic perspective.

What makes montmorillonite unique?

Amlan mines, produces and sells calcium montmorillonite, and it’s the only clay-based material that we use in our products for food production animals.

Calcium montmorillonite is a highly effective clay and it’s more effective than zeolites or attapulgite that are a couple of alternatives that a customer might find in the marketplace.

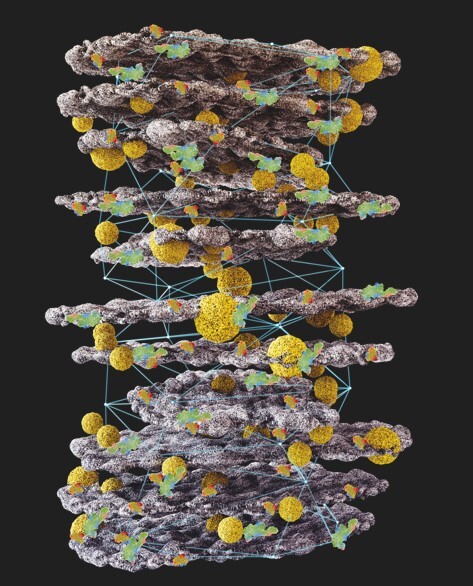

Beyond that, Amlan’s montmorillonite, through our Oil-Dri parent mine, is a very specific material that has a unique morphological structure that includes elements in it called opal-CT lepispheres which provide a more rigid phyllosilicate or clay structure during processing.

This dramatically increases the surface area of the clay, which is already very porous, allowing a significant amount of adsorption to the clay particle as it is ingested by the animal and passes through its GI tract.

This makes the product that Amlan sells uniquely efficacious and offers the best return on investment. Again, a customer can use a wide range of different types of clays. We believe montmorillonite is the premium clay offering, and because of the vertical integration of Oil-Dri, this allows us to have the consistency of mining, production, and delivering the product to our customer, which is unique.

When a customer buys clays on the open market, they might be getting a local clay or a clay from Europe or Africa, and every load may come from a different source and range in quality and consistency. Our clay comes from a selectively sourced mine in the United States where we have quality control over the complete process.

Tell me about your mines.

Oil-Dri was founded in 1941, so we have a long legacy of being in this business and we’ve been vertically integrated really from our inception to today. We control and operate multiple mines across the United States. Oil-Dri sells across multiple industries, and we use clay from different mines for different industries based on their unique properties and needs.

The mine that we utilize for animal nutrition is selectively sourced, but we have literally hundreds and hundreds of years of reserves there and because of that, we can ensure the consistency and uniformity of our product day by day. So, when a customer buys a product today from Amlan, they will get the same product five years from now. It will be identical in its composition and its efficacy for the animal.

Clay-based solutions are natural solutions. The products that we sell into animal nutrition are not treated with any chemicals. They're simply thermally processed to make them active and efficacious and that allows us to provide a solution that is very different than a chemical or pharmaceutical product that a customer might have the option to use.

Which markets does Amlan sell into?

We actually sell two different portfolios around the world. In our international markets, we sell a portfolio of products that are led by Calibrin-Z, Calibrin-A, Phylox and NeutraPath. These are products that have a long history of use in various world areas and are excellent mycotoxin binders that can also mitigate bacterial toxins.

In the U.S., we sell a range of products that really promote the animal's optimal gut health, help balance its microbial ecology and maintain a strong immune system. The product allows the animal to reach its optimum genetic performance and provides an economic benefit to the producer.

Sorbium XL is our flagship product in the US market, along with Sobium which has a little finer particle size than the XL brand. We also have a product called Ambio that we will be launching soon that is specifically targeted to help promote optimal gut health and maintain the animal’s optimum performance. Another product that we will be selling in the US soon is called Enterotec. Customers have struggled with resistance to antibiotics and other types of products used in coccidiosis, and Enterotec can be part of the solution to help animals maintain overall performance and immune status and promote the animal’s optimum genetic potential.